PP Plastic Damper: Function, Types, and Applications

Category : Blog

PP plastic dampers introduction:

PP plastic dampers are crucial components used in ventilation systems to control the flow of air. They play a vital role in regulating air volume, ensuring efficient airflow, and maintaining optimal environmental conditions. In this article, we will explore the function of damper valves, discuss dampers used for precise flow control, differentiate between dampers and valves, introduce butterfly dampers, highlight three common types of dampers, and delve into the applications of pressure relief dampers.

Function of PP Plastic Damper Valve:

The primary function of a damper valve is to regulate the flow of air within a ventilation system. It allows for the adjustment and control of air volume, ensuring proper air distribution throughout the system. By modulating the position of the damper, the airflow can be increased, decreased, or completely shut off, depending on the requirements of the space being ventilated.

Dampers for Precise Flow Control:

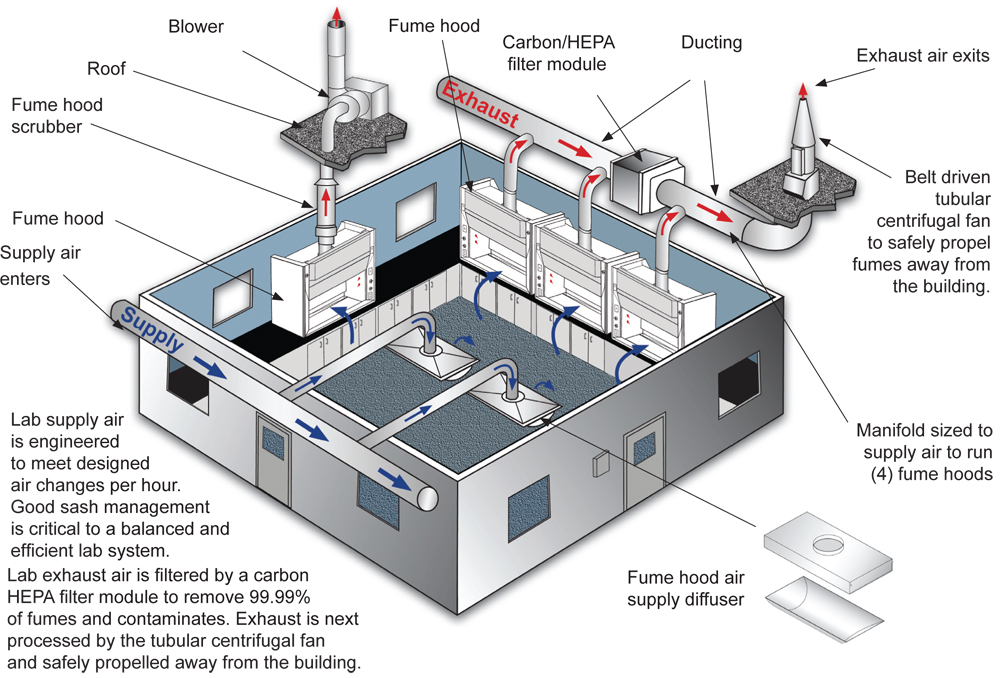

When precise flow control is necessary, specialized dampers come into play. These dampers are designed to provide accurate and fine-tuned adjustments to the airflow. They offer enhanced control over the volume and velocity of air, making them suitable for applications where precise airflow management is crucial, such as laboratories, cleanrooms, and industrial processes.

Difference between a PP Plastic Damper and a Valve:

While the terms “damper” and “valve” are sometimes used interchangeably, they have distinct characteristics. A damper is specifically designed for airflow control within ventilation systems. It regulates the flow of air by adjusting the position of a blade or plate. On the other hand, a valve is a broader term that encompasses various devices used for controlling the flow of fluids or gases. Valves are commonly found in plumbing systems, industrial processes, and other applications beyond ventilation.

Introduction to Butterfly Damper:

A butterfly damper is a specific type of damper characterized by its disc-shaped, butterfly-like blade. This blade is connected to a central spindle, allowing for 90-degree rotation. By rotating the blade, the airflow can be controlled effectively. Butterfly dampers are commonly used in HVAC systems, where quick and reliable airflow modulation is required.

Three Types of PP Plastic Dampers:

- Parallel Blade Dampers: These dampers feature parallel blades that move in unison to adjust the airflow. They are suitable for applications requiring basic flow control.

- Opposed Blade Dampers: In opposed blade dampers, the blades move in opposite directions. This design allows for precise modulation of airflow and is commonly used in applications requiring accurate control.

- Single Blade Dampers: Single blade dampers have a single blade that pivots to control airflow. They are ideal for applications where space is limited or a compact design is required.

Applications of Pressure Relief Damper:

Pressure relief dampers are specifically designed to relieve excess pressure within a ventilation system. They are commonly used in areas where pressure imbalances may occur, such as commercial kitchens, laboratories, or industrial facilities. These dampers help maintain proper airflow and prevent damage to the system caused by excessive pressure.

Conclusion:

PP plastic dampers play a vital role in ventilation systems, ensuring efficient airflow and maintaining optimal environmental conditions. Understanding their function, types, and applications is crucial for designing and implementing effective ventilation solutions. Whether it’s precise flow control, the difference between dampers and valves, the versatility of butterfly dampers, or the need for pressure relief, these aspects contribute to the overall efficiency and performance of ventilation systems.